Choosing the Right China PPGL Coil Supplier: A Buyer’s Guide

Wuxi, Jiangsu Nov 10, 2025 (Issuewire.com) - How to evaluate PPGL quality, capacity, lead time, price-value, and technical support before placing a purchase order.

Why PPGL

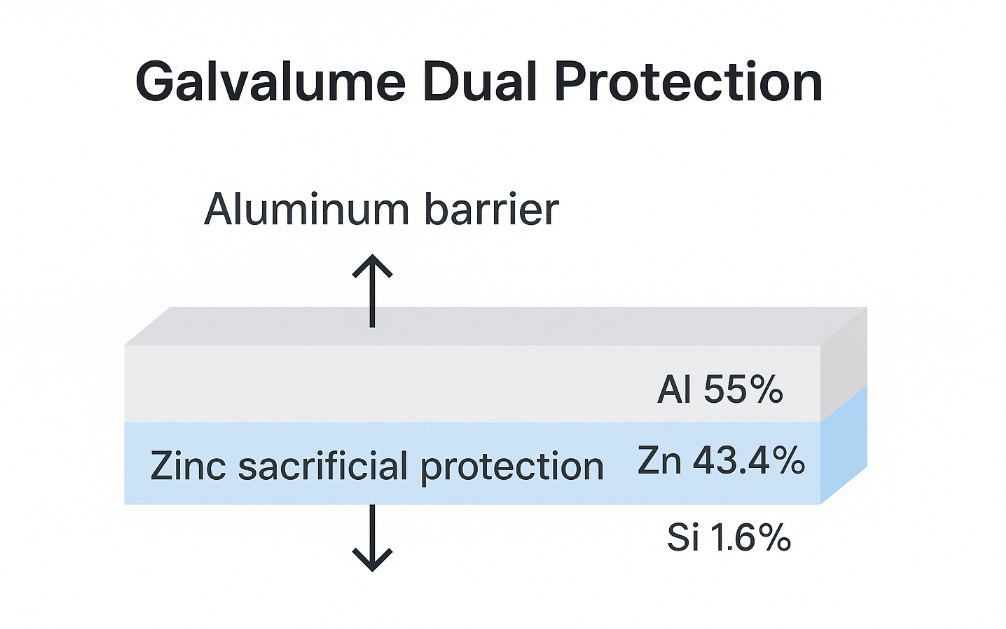

PPGL (pre-painted galvalume) combines aluminum's barrier protection with zinc's sacrificial behavior. Compared with PPGI (pre-painted galvanized), PPGL often delivers better edge protection and color stability in coastal or industrial environments.

PPGI vs PPGL (Substrate Difference)

Item PPGI PPGL

Metallic coating Pure zinc (galvanized) Galvalume Al 55% / Zn 43.4% / Si 1.6%

Edge & scratch behavior Mainly sacrificial (Zn) Barrier (Al) + sacrificial (Zn)

Typical environment General inland Coastal / industrial / higher UV

Relative service life Baseline Often longer (application-dependent)

Lifespan also depends on the paint system (PE/SMP/HDP/PVDF), coating mass (AZ), and paint thickness.

Key Applications

Building & Construction

Roofing, wall cladding, and pre-engineered buildings where UV and weatherability matter.

Industrial & Others

Agricultural buildings, HVAC, outdoor signageanywhere long-term exposure is expected.

How to Choose a China PPGL Coil Supplier

1) Manufacturing Quality & Process Control

Verify AZ coating mass, paint system, and curing conditions.

Ask for recent test reports: salt spray, QUV, bend, and impact.

Check batch traceability, E (color difference), and gloss tolerance.

Request production photos/videos and QA records from the last 6-12 months.

2) Capacity, Lead Time & Reliability

Confirm monthly capacity and current line loading.

Compare standard vs. peak-season lead times.

Ask about backup lines and outage contingency.

Collect evidence: packing lists, BL copies, shipment schedules, and references.

3) Price-Value, Not Just Price

Direct manufacturers can reduce costs, but evaluate lifetime value: higher AZ mass and HDP/PVDF systems may cut warranty risk and repaint costs.

4) Technical Support & Customization

Look for suppliers who advise on PPGI vs PPGL by environment and service-life goals. Expect flexible thickness (0.3-1.2 mm), custom color/gloss, and paint system options (PE/SMP/HDP/PVDF).

Market Outlook

Urbanization, infrastructure upgrades, and "build-for-long-life" standards are supporting PPGL demand. Newer HDP/PVDF systems continue to improve UV stability and color retention.

Request a Spec-Matched Quote

Share thickness, width, AZ mass, paint system, color, and annual volume. We will recommend the right PPGL spec for your environment and budget.

FAQ

Is PPGL always better than PPGI?

No. Choose by environment and lifecycle target. PPGL generally suits coastal/industrial exposure; PPGI can be economical for mild inland conditions.

Which topcoat should I choose (PE/SMP/HDP/PVDF)?

HDP/PVDF for strong UV and long color retention; SMP for balanced cost/durability; PE for short-to-mid term or indoor use.

What thickness range is typical?

About 0.3-1.2 mm depending on structural needs, forming radius, and local codes.

Jiangyin Everest Steel Co., Ltd.

https://everesteel.com/

Address:

22/F, Zhifu Building, No. 299, Tongdu North Road, Jiangyin, Wuxi, Jiangsu

Call Us:

+86-158-5259-6209

7 x 24 hours

E-mail:

[email protected]

Jiangyin Everest Steel Co., Ltd. mainly supplies color-coated steel coil, pcm, vcm, pre-painted steel, print steel, pre-painted stain-less steel, pre-painted aluminum, laminated steel, writing board steel, etc.

Media Contact

Jiangyin Everest Steel Co., Ltd.

+86-158-5259-6209

22/F, Zhifu Building, No. 299, Tongdu North Road, Jiangyin, Wuxi, Jiangsu

More On Starmediaplanet ::

- A Statewide Journey Captured in Print — Dean B. Settle’s Inside Nebraska Courthouses Explores Nebraska’s Courthouses

- How to Verify Quality When Choosing a China Leading Energy Storage Battery Manufacturer

- Dr. Usama Bukhari: Pioneering Medical Education and Innovation in Internal Medicine

- A Good Formula Is More Than Freeze-Drying: The Fusion Nutrition Concept by Yupai

- Hello Movers LLC Expands Reliable Moving Services Across the Tampa Bay Area

Source :Jiangyin Everest Steel Co., Ltd.

This article was originally published by IssueWire. Read the original article here.